-40%

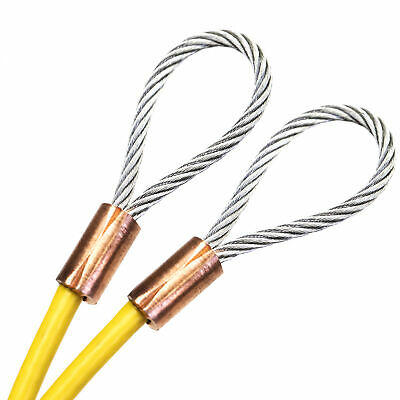

1/4" COATED GALVANIZED STEEL CABLE COPPER SLEEVE, 1-75ft (Clear,Yellow)

$ 7.12

- Description

- Size Guide

Description

CABLE SPECIFICATION1-75 feet, Vinyl Coated Galvanized Steel Cable Wire

Jacket Color: Clear, Yellow

Outer Diameter: 1/4 inches with coating

Core Diameter: 3/16 inches galvanized steel

Maximum Tensile Strength: 3700 lbs

Refers to federal RR-W-410H specification

Cable End Configuration: Looped on both ends with copper sleeve

(Copper will naturally change colors over time, developing a protective "patina" coating. Manufacturer suggest copper sleeve may hold up to 100% tensile strength of braided cable vs 60% with aluminum sleeve)

*** Length indicated on this listing is measured from the end of the loop(s) ***

IMPORTANT INFORMATION

Maximum Tensile Strength ratings are listed for comparison purposes only. Actual operating loads may vary, but should never exceed recommended design factor or 12% of maximum tensile strength. These cables are not designed for overhead lifting or aircraft use; never exceed working load limit. maximum tensile strength is not considered safe working load limit. PHAT SATELLITE INTL assumes no responsibility for the use, misuse, or misapplication of its products. Products are sold with the specific understanding that the purchaser and/or user are thoroughly familiar with their proper use. We recommend buyer to consult with a licensed engineer for proper usage safety.

***DUE TO CUSTOMIZATION AND SAFETY RISKS THIS ITEM CANNOT BE RETURNED***

Working Load Limit (WLL) – The Working Load Limit is the maximum load which should ever be applied to the cable, even when new or when the load is evenly distributed – straight line pull only. Avoid side loading. All ratings are based upon regular environmental conditions; conditions; attention must be given to unusual conditions such as severe temperature, chemical solutions or vapors, prolonged immersion in salt water, etc.

Proof Test Load (Proof Load) – The term “Proof Test” assigns a quality control test applied to the product for exclusive function of exposing flaws in material or build. The Proof Test Load (normally 2x the WLL) is load which the cable underwent & sustained without malformation when new and under laboratory test conditions. The Proof Test Load does not mean that the WLL should ever be exceeded.

Breaking Strength – Breaking Strength is the average force at which the wire rope, in the condition it would leave the factory, has been found by representative testing to break, when a constantly increasing force is applied in direct line to the product at a uniform rate of speed on a stander pull testing machine. Proof testing to twice the WLL does not apply to hand-spiced slings. Remember: Breaking Strength, when published, where obtained under controlled laboratory conditions. Listing the Breaking Strength does not mean the Working Load Limit should ever be exceeded. Do not use breaking strength as a criterion for ser vice or design purposes. Refer to the Working Load Limit instead.

Design Factor – An industry term usually computed by dividing the Breaking Strength by the WLL and generally expressed as a ration (ex: 7:1).

Shock Load – A load resulting from rapid change of movement, such as impacting, jerking or swinging of a stack load. Sudden release of tension is another form of shock loading. Shock loads are generally significantly greater than static loads. Any shock loading must be considered when selecting the item for use in a system. Avoid shock loads as they may exceed the Working Load Limit.