-40%

3M Cubitron II 982C 7" Wet/Dry Ceramic Grain Fiber Grinding Disc, 25.Discs

$ 31.65

- Description

- Size Guide

Description

3M Cubitron II Fibre Disc 982C3M Cubitron II Fibre Disc 982C uses 3M Precision-Shaped Grain to generate up to twice the cut-rate, durability, and life of other fiber discs when grinding carbon steel — all with less grinding pressure required by the operator. That means less operator fatigue, faster throughput, and more parts per disc when tackling medium and high-pressure grinding applications.

3M Precision-Shaped Grain maintains super-sharp points that cut exceptionally fast with less pressure

Disc life is significantly longer, completing more parts per disc and requiring fewer disc changes

Reduces changeouts and downtime in manual, robotic and pressure-assisted applications

Triangular shaped ceramic grain lasts up to two times longer than other ceramic abrasives—it wears evenly, runs cool, and optimizes mineral breakdown

Stiff fiber backing and a strong resin bond provide durability and tear-resistance for heavyweight applications such as high-pressure weld grinding and beveling

Raising the Bar in Abrasives

This premium fibre disc raises the bar in speed and stock removal. With 3M Precision-Shaped Grain, 3M engineers developed a process for generating triangular shaped ceramic grains that are electrostatically oriented on the backing to form sharp peaks and maximize cutting potential. These peaks act like individual cutting tools that slice through metal, and continuously fracture into new sharp cutting edges. The grains wear evenly and self-sharpen, reducing heat due to friction to deliver up to twice the life of other fibre discs, with less grinding pressure. The result is that 3M Cubitron II Fibre Disc 982C out-cuts and outlasts every conventional ceramic industrial abrasive disc on the market, maximizing productivity and helping reduce your overall abrasive spend.

Ideal for Robotic Weld Grinding.

In medium and high-pressure applications like robotic weld grinding, it's important to choose a high-performance abrasive that cuts fast and lasts long. The self-fracturing mineral in 3M Cubitron II Fibre Disc 982C will keep your robot grinding welds long after other abrasives call it quits, reducing downtime and maximizing efficiency. Curious about robotic material removal? The dedicated team of 3M robotics application engineers are ready to partner with you on your automation journey, from idea to implementation.

Long-lasting fibre discs maximize efficiency in robotic grinding applications.

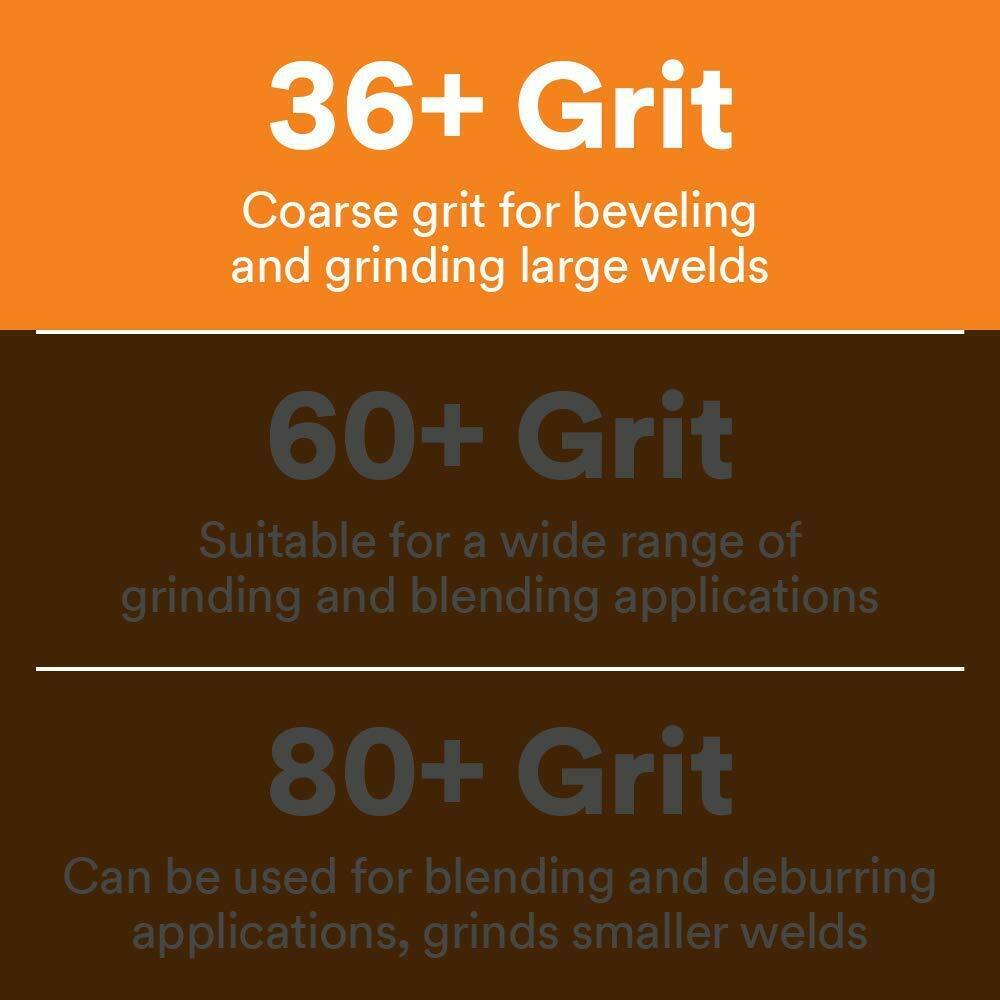

3M Cubitron II Fibre Disc 982C comes in a range of grits to suit your application needs — from coarse grinding large welds to blending and deburring.

36+ grit fibre discs are ideal for beveling and grinding large welds, providing maximum stock removal and a coarse finish

60+ grit fibre discs cover a wide range of grinding and blending applications, providing good stock removal and a finer finish than 36+ grit discs.

80+ grit fibre discs are best suited for grinding smaller welds, blending and deburring. They leave behind a finer finish than coarse grit discs.

3M offers a complete right angle system: fibre discs, backup pads and power tools.

These components work together to optimize the performance of 3M abrasives.

Your Total Solution Supplier

Combined with 3M power tools and application engineering expertise, 3M Cubitron II Fibre Disc 982C is part of a complete abrasive solution. With the 3M abrasive solution, you’ll have the right abrasives, the right tools and industry-leading application engineers to help you take your shop to the next level.

Product description

Product Description

Boost productivity in your shop with the fast-cutting, long-lasting 3M Cubitron II Fibre Disc 982C. This ceramic grinding disc uses 36+ grit 3M Precision-Shaped Grain to generate up to twice the cut-rate of other fibre discs. This ceramic grain lasts exceptionally long, continuously fracturing into super-sharp points and edges that slice cleanly through metal. By grinding faster than other discs, this 3M fibre disc allows you to complete more parts and boost productivity. The built-in GL (Grit Lok) quick change attachment allows for easy disc changes. A stiff fiber backing and strong resin bond mean this resin fibre disc is durable enough for heavyweight applications like high-pressure weld grinding and beveling. With durability comes longer abrasive life, reducing the amount of time spent changing out abrasives and further boosting productivity. All of these metal grinding productivity gains come with less grinding pressure exerted by the operator. In robotic or pressure-assisted operations, 3M Cubitron II Fibre Disc 982C helps reduce downtime in the cell by lasting exceptionally long and maintaining a high cut-rate through the entire life of the disc. This 5 inch grinding disc can be used with either pneumatic or electric tools. 3M 982C fibre disc is optimized for use on carbon steel. For stainless steel, consider using 3M Cubitron II Fibre Disc 987C.

From the Manufacturer

The 3M™ Cubitron™ II Fibre Disc 982C with GL attachment delivers superior optimum performance and productivity with less operator fatigue when tackling high pressure grinding applications such as medium to heavy-duty stock removal on carbon steel applications. Featuring 3M’s exceptionally high-performing ceramic Precision-Shaped Grain (PSG) combined with a stiff fiber backing, this disc is an excellent choice for edge chamfering, beveling, and removing carbon steel welds, mill scale, pits and imperfections, machining grooves, and more. It delivers outstanding cut rates and disc life, runs cooler, and requires less grinding pressure than other conventional ceramic discs. The stiff fiber backing and strong resin bond provide added durability and tear-resistance for heavyweight applications such as high-pressure weld grinding, and support wet or dry applications.

The Nitty Gritty

This disc has a center hole fitted with a single-use thin gauge metal attachment with tabs that insert into the slots of a 3M™ GL Disc Pad Hub for use on a right angle grinder (hub and tool sold separately).

3M-patented Cubitron II products have raised the bar for high-performing abrasives. 3M engineers started with 3M ceramic abrasive grain and used proprietary precision-shaped grain (PSG) technology to generate triangular shaped grains that are electrostatically oriented on the backing to form sharp peaks and maximize cutting potential. These peaks act like individual cutting tools that slice through metal, wear evenly, and continuously shelf-sharpen as the points break off, reducing heat due to friction for up to twice the life of other fiber discs, with less grinding pressure. The result is that Cubitron II discs outcut and outlast every conventional ceramic industrial abrasive disc on the market, with less grinding pressure, maximizing productivity and minimizing operator fatigue.

Experience the Powerful Performance of 3M™ Cubitron™ II

3M Cubitron II products have raised the bar for high-performing abrasives. 3M™ Precision-Shaped Grain outcuts and outlasts conventional ceramic industrial abrasives and requires less grinding force to achieve superior performance. The result is that operators can grind faster and complete more parts per disc with less muscle-work and fatigue.

To create PSG, 3M engineers started with 3M™ Ceramic Abrasive Grain and used proprietary technology to form the grains into triangular structures and electrostatically orient them on the backing to form sharp peaks that maximize cutting potential. These peaks slice cleanly through metal like a knife through butter, rather than gouging or plowing as traditional abrasives do, and continuously self-sharpen as the points break off. This generates a super-fast cut and lessens heat build-up due to friction, reducing heat-related stress cracks and discoloration.

PSG also wears evenly, and because the abrasive itself stays cooler and sharper, Cubitron II products last significantly longer than their conventional ceramic counterparts, ensuring extended high performance in production applications.

Disc Changes are Quicker with GL Quick Change Attachment

The GL or Grit Lok attachment system was designed by 3M to provide convenient, reliable attachment to and removal from the tool, making it easy to switch discs and face plates between applications. A GL fiber disc has a center hole with a single-use thin gauge metal attachment with tabs that insert into the slots of a 3M GL Disc Pad Hub.

Fiber Discs—Ideal for Tough Grinding Applications

Fiber discs are heavy-duty discs ideal for weld removal, grinding, and blending large and small areas of metal surfaces. They feature a tough, stiff backing made from hardened fibers that resist wear and can handle tough grinding applications.

About 3M Abrasive Systems

For more than a century, 3M has applied innovation and technology to improving our customers’ lives and supporting their business goals. Today the company, from its headquarters in St. Paul, Minnesota, serves industrial and commercial customers and consumers in nearly 200 countries. Abrasive Systems products, including a complete line of coated abrasives, microfinishing and microreplicated abrasives, and hardware accessories, provide the finishing touch for almost any surface modification application. The 3M brand, across thousands of products, represents consistency, superior quality, and value.